Over the weekend, both the St. Joseph’s Hospital 4.6 MW CHP Plant (Syracuse, NY) and the 7.9MW CHP Plant at Penn State Hershey Medical Center (Hershey, PA) will be undergoing the semi-annual shutdown and inspection of their cogeneration plants. Not only does Cogen Power Technologies have the experience in developing and constructing unique CHP Plants, we offer service contracts to aid in the preparation and execution of safe and successful diagnostics and maintenance practices along with facility staff.

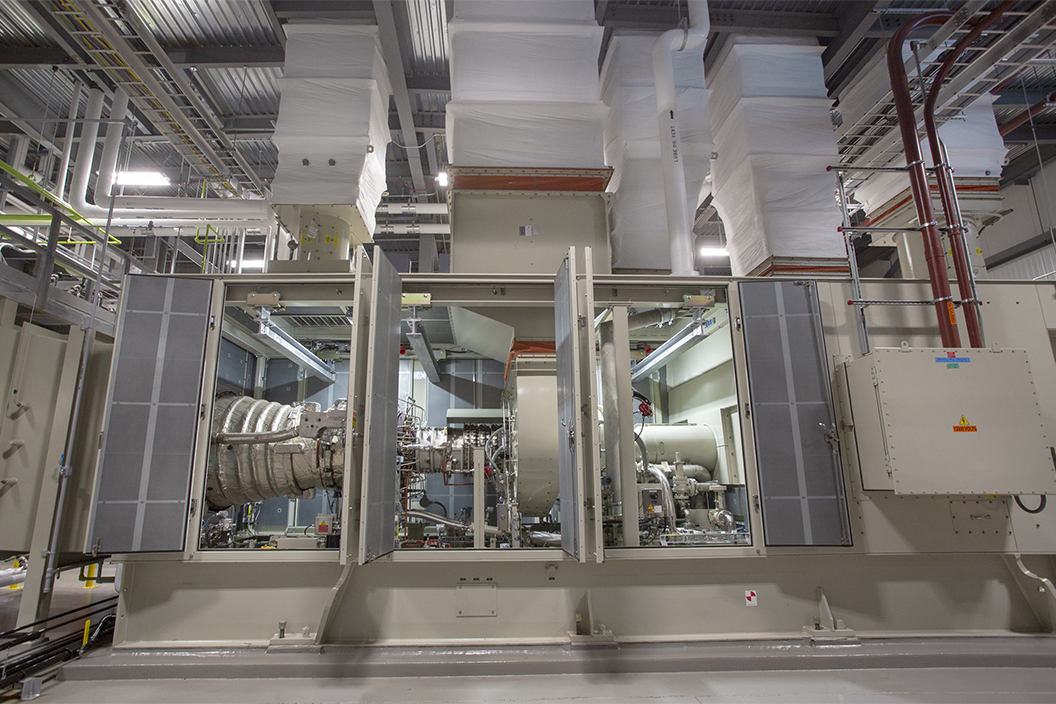

Semi-annual shutdowns and inspections are critical to the operational success of a cogeneration plant to ensure that the plant is performing to the pedigree of their capabilities. During the shutdown, there are three major components of the plants that will be inspected which include the turbine, HRSG (Heat Recovery Steam Generator), and gas compressor. All three must operate in parallel for the plant to generate the energy required by the facility, so they all must be shut down at the same time.

The St. Joseph’s Hospital CHP Plant and the Penn State Hershey Medical Center CHP Plant have the same three major components of equipment, although be it different sizing to meet the individual hospital needs. At each facility, the turbine will undergo filter changes, testing of switches and transmitters, a compressor water wash, and a borescope of the engine at a minimum. The HRSG will be shut down for removal of boiler internals for inspection. The gas compressor will have filter changes, the alignment checked, and testing of switches and transmitters as well. Other equipment inspected and maintained during the shutdown down will include auxiliary equipment for the plant, such as pumps, motors, and electrical equipment.

In-between semi-annual shut downs, our staff works day-to-day on addressing technical questions and performing routine preventative maintenance of the plant. For this week, CPT will work closely with the facility staff and equipment technicians on the checklist of maintenance items to be completed to ensure that it is successful. The next shutdown will be slated for the fall, which will include the same inspections and maintenance of the major equipment.