Project Description

Penn State Hershey Medical Center CHP Plant

In light of the many recent weather-related crises in the Northeast, Penn State recognized the vulnerability of their aging infrastructure, and instead of simply replacing equipment, they chose cogeneration to add another level of protection to safeguard the campus. Penn State Hershey Medical Center is a busy Level 1 Adult and Level 1 Pediatric trauma center (only facility in the state for both) in Central Pennsylvania with the 551 beds. The 550-acre campus supports a medical college, student housing, and research facilities.

Ready to replace their aging electrical infrastructure, Penn State examined their ability to withstand extreme weather conditions and other external forces, and determined that they needed to fortify their systems and considered cogeneration as a solution. The Cogen team was selected by Penn State to begin the $23 Million Design-Build CHP plant project in 2016. Our team reevaluated the findings of a prior study and concluded that a larger turbine, despite a higher initial cost, would better serve the campus and increase their savings over time. To help allay the added expense, Cogen assisted in securing a $940,000 grant from the Commonwealth of Pennsylvania and another $500,000 from the local utility.

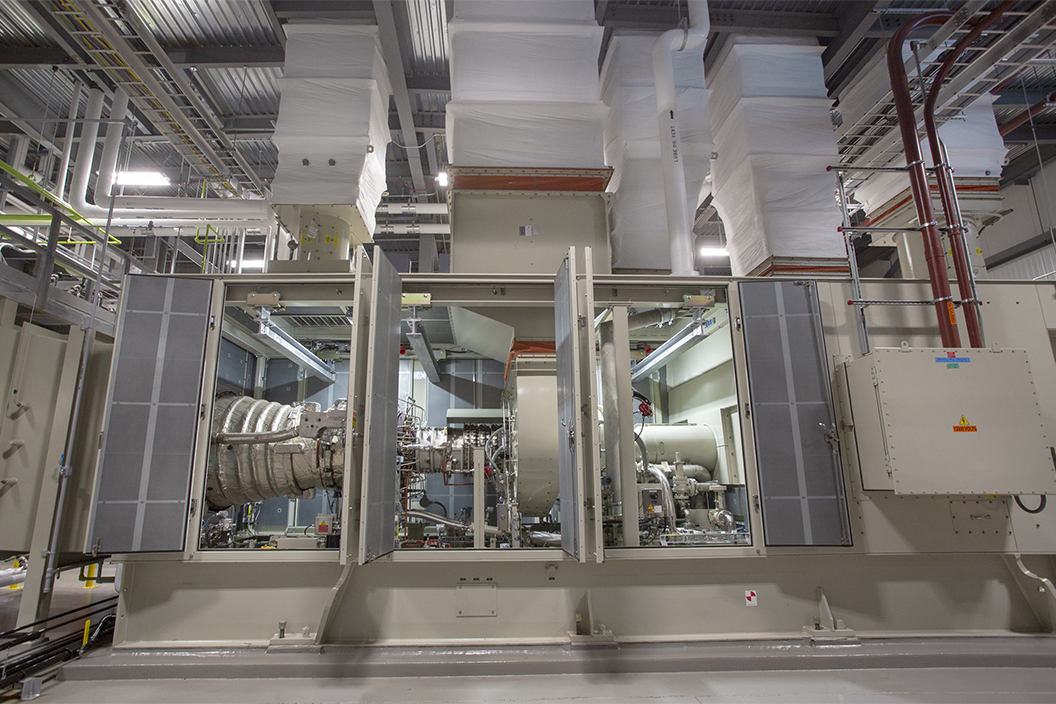

The new CHP Plant features a 7.9 MW natural gas fired turbine paired with a 80,000 pph Heat Recovery Steam Generator, a 1 MW Black Start Diesel Generator, and a state-of-the-art Load Management System that controls the supply of electricity. The location for constructing the 10,500 SF plant posed several challenges to our team. Porous soil conditions required improvement to the base by drilling columns and filling them with stone to adequately support the building foundation and heavy equipment. In addition, a highly-sensitive research facility is in close proximity to the building, so added measures were introduced to lessen noise-levels during construction (through close coordination) and during operation (noise dampers installed on the turbine vents).

The plant will provide an added layer of resiliency and cost efficiency for the hospital, as well as cost avoidance for pending boiler replacements. Cogen will support operations for the first 12 months.

Commercial Operations commenced in January 2019. The plant is projected to meet 54% of the campus’ electric consumption and 98% of the thermal consumption and reduce the total utility expense by $3 Million annually. The plant will reduce carbon emissions by over 46,000 tons per year roughly the equivalent of removing 7,500 cars from the road.