What is Cogeneration?

Cogeneration, commonly referred to as “Combined Heat and Power” or “CHP”, is the process of using one fuel source to produce two individual energy products. Significantly more efficient than traditional power generation, cogeneration can dramatically reduce utility costs while providing numerous benefits to including increased reliability, predictability, and significant reduction of carbon emissions.

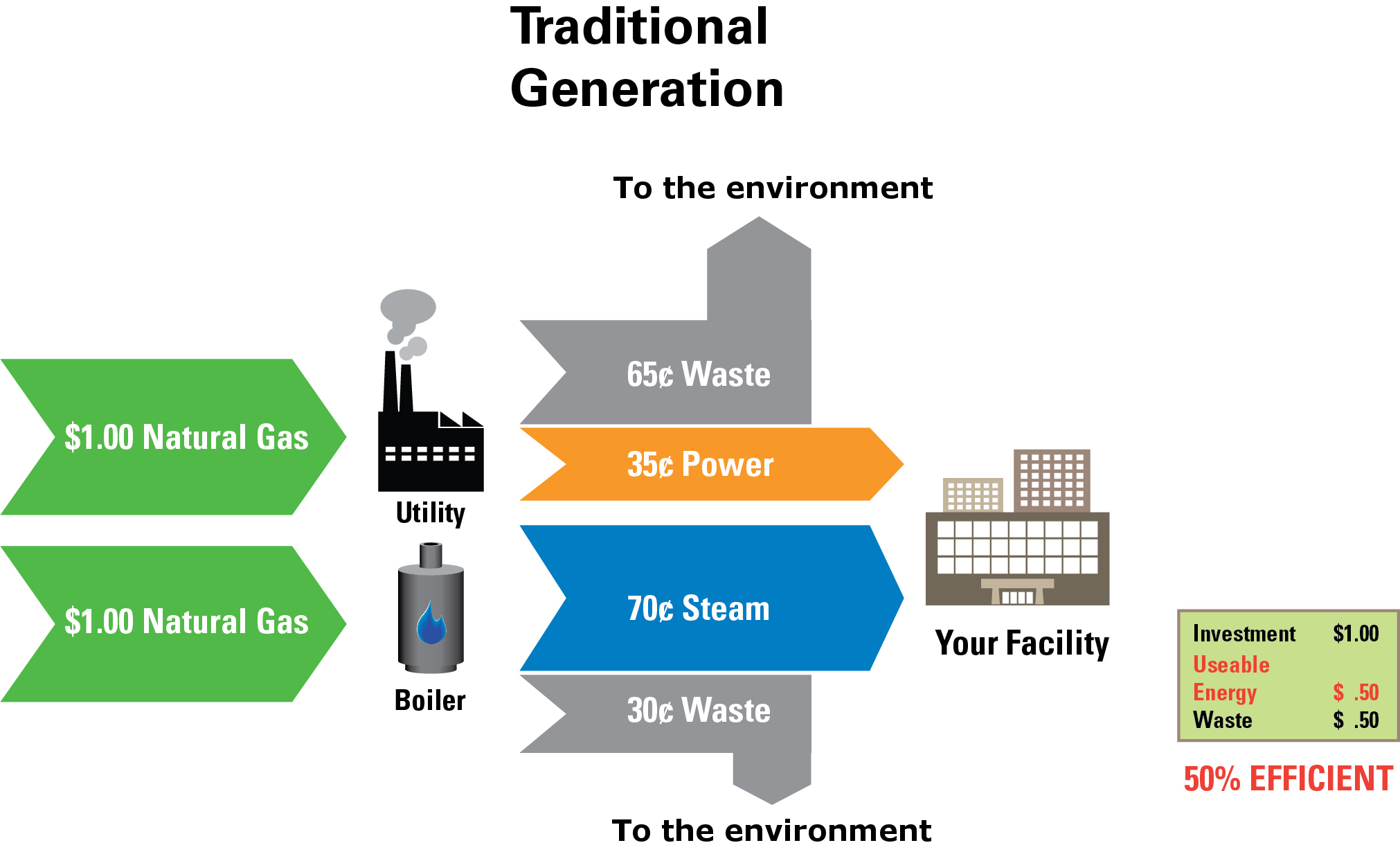

Traditional Power Generation

Traditional power generation involves two separate processes. One process is for producing electricity. The other process is for producing thermal energy. Commonly, a utility will use conventional fossil fuels, such as coal, oil, or natural gas, to generate electricity.

This is used to produce thermal energy then it is made available for purchase by the consumer. Also requiring heating and cooling, the consumer will, in addition, have an on-site boiler or furnace to generate thermal energy. In this two-pronged approach, two fuel supplies are utilized and a substantial amount of heat and energy “waste” is lost to the environment.

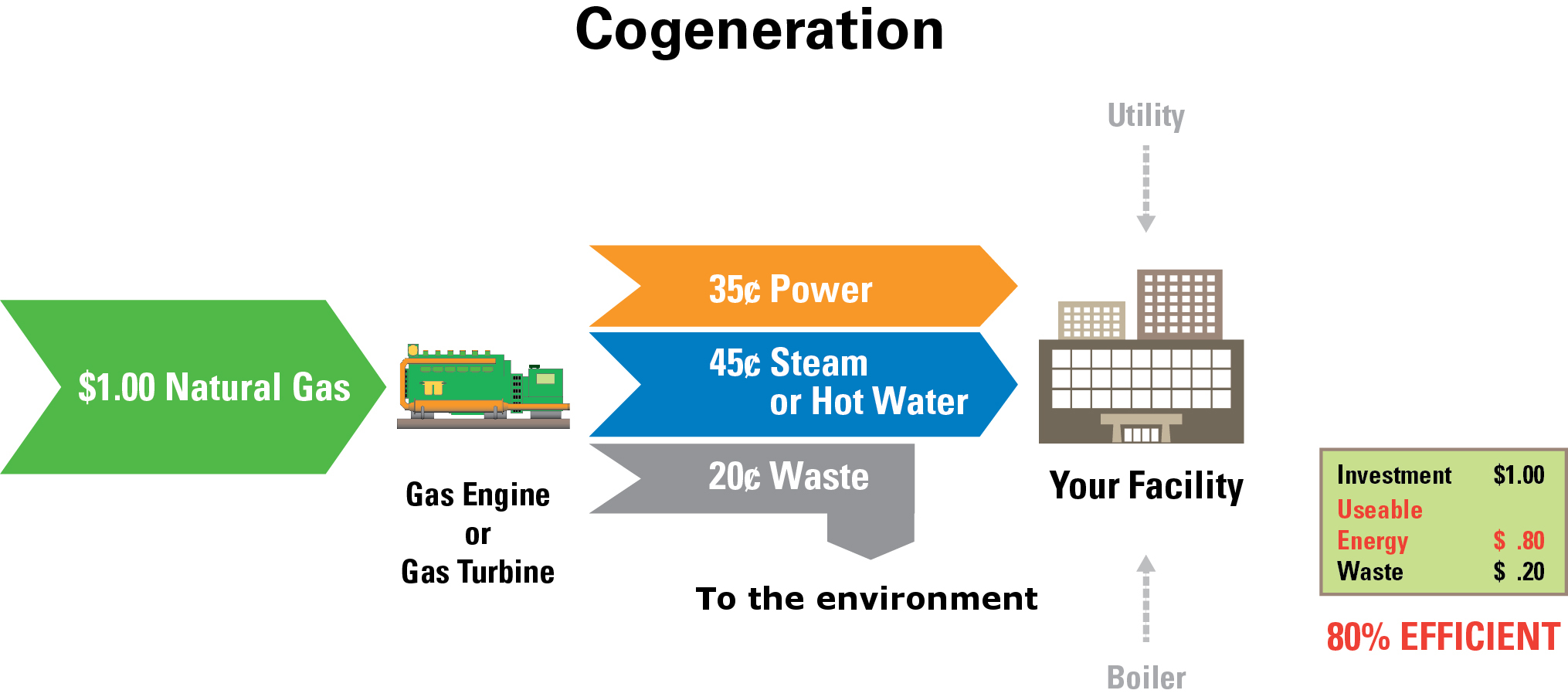

Cogeneration

Cogeneration is a technology that can be used to replace or complement traditional power generation processes. In cogeneration, thermal “waste” from generating electricity is delivered as a source in a highly-efficient process to supply useable thermal energy for heating and cooling systems.

Typically onsite or in close proximity to the consumer, cogeneration plants use a single fuel source; opting for clean fuels such as natural gas or biomass to produce both electricity and thermal energy in one efficient process. In the process, an internal combustion engine, such as a gas turbine, uses the primary fuel source to generate electricity.

In turn, a large amount of heat is generated as a by-product. Typically lost in traditional power generation, this thermal energy is made in to a source of energy for a heat recovery steam generator or HRSG, that produces steam or hot water for heating or other uses.

Why Cogeneration?

Inherently efficient, cogeneration eliminates waste and can often double energy production efficiency to significantly reduce annual utility costs, as well as provide a number of remarkable operational benefits.

Qualified Multidisciplinary Team & Partners

Real people who are experts at their craftLearn About the Cogen Team

Program Developers and Managers; Mechanical, Electrical, Structural, and Computer Engineers; Architects; Plant Operators and Plant Managers; Commissioning Professionals; and General Contractors

Extensive Project Experience

Since 2009, our team has worked on over 25 different CHP projects and feasibility studies.Explore our Work

We know how to leverage our project experience to deliver the most cost effective and efficient solution. Review some of our projects.

Financing, Ownership, and Operation

We pass on the knowledge of owning and operating a Cogen Plant to youUnparalleled and Invaluable Experience

Cogen is the 3rd party owner/operator of a 3.6 MW CHP plant that has produced over 80 Million kWhs since 2009.

Support for Cogen Operations

We train cogen operators and offer ongoing supportWe train, transition and supervise your plant operators

We have gained great industry knowledge from owning and operating our own Cogen plant. That knowledge is a powerful resource for the continued success of your cogen facility.

Our Portfolio

Explore successful projects implemented and currently supported by Cogen Power Technologies