PROCESS OVERVIEW

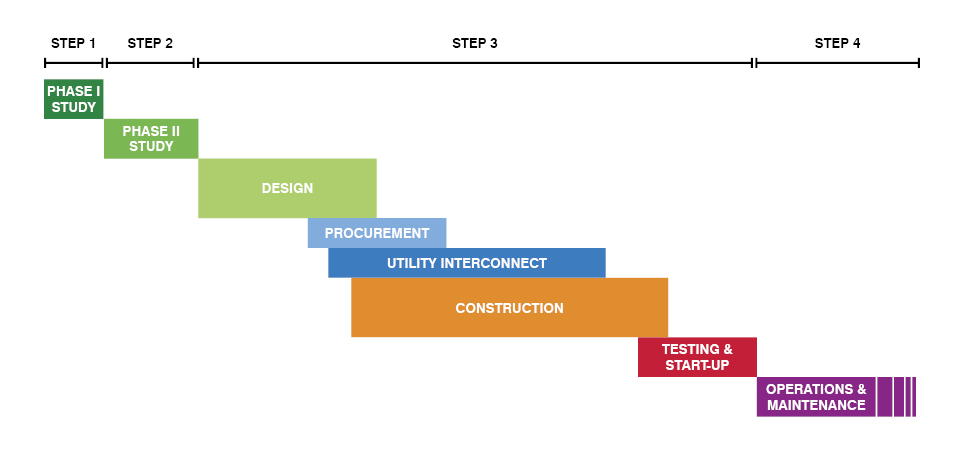

Four steps deliver success.Cogen Power Technologies (Cogen) uses a four step process to evaluate, design, and build cogeneration plants that meet Customer needs at a value engineered cost.

Step One: Phase One CHP Feasibility Study

The first step in the process is for Cogen to perform a Phase One CHP feasibility study. The intent of this effort is to quickly assess whether or not the Customer’s site meets the fundamental requirements necessary for successfully implementation of a Combined Heat and Power (CHP) Plant, and if the benefits derived from the CHP Plant meet the customers financial, environmental, operational, and community needs. The deliverables of this effort are:

- ROM (Rough Order of Magnitude) Project Cost with Simple Payback calculation

- Estimated Annual Utility Savings

- Selection of Prime Mover technology

- Estimated annual Greenhouse gas emissions reduction

- Estimate Project schedule

- Recommendation on whether or not CHP “makes sense” for the Customer

Step Two: Phase Two CHP Feasibility Study – Design Development and Project Cost

Now that the Customer has decided to move forward in the process, Cogen prepares preliminary designs to make major equipment selections, determines how best to seamlessly integrate the new CHP plant into the existing boiler plant, and obtains major subcontractor pricing.

During this phase, Cogen engages the local utility in discussions to ensure there are no “Show Stoppers” regarding the electrical interconnection of the CHP Plant to the utility’s electrical distribution system. Cogen also determines if the natural gas service has sufficient capacity to supply the new plant.

Cogen’s operational experience is factored into this step. Cogen’s in-house CHP Plant Operational Staff carries out a thorough review of the design approach and interacts with the customer’s facility staff to systematically resolve any existing plant issues with the implementation of the new CHP Plant. Cogen’s design-builder affiliate, Bette & Cring Construction Group, will be engaged in this phase to provide value in the construction component of the effort to ensure the most cost effective building solution.

Cogen will conduct a thorough financial savings analysis that highlights the estimated annual savings projections, the simple payback of the investment, the net present value of the investment, an assessment of what type of subsidies are available, and a high level review of the potential benefits the customer may be able to realize.

Finally, Cogen will provide a Project Schedule, Guaranteed Maximum Price, Equipment Performance guarantees, and a detailed project scope that we refer to as the Owner’s Program. The Owner’s Program defines the scope of the project, the assumptions used to develop the schedule and cost, and the responsibilities of the Design Build Team and Customer.

Step Three: Design, Build, and Commission the CHP Plant

The Cogen Team – including its design partner and construction affiliate – will now methodically design, build, and commission the CHP Plant. An experienced Construction Project Manager will manage the overall project with a Technical Project Manager to drive the design, procurement, and installation of the major MEP equipment.

Bi-weekly customer meetings will be held upon contract placement through CHP plant turnover. This ensures Customer involvement throughout the project.

Management of the local utility electrical interconnection project is a key component of this effort and is closely monitored by our Electrical Interconnection Expert.

Cogen firmly believes that a third-party Commissioning Agent should develop and lead the overall plant test plan and independently confirm that all functionality has been successfully tested. This provides the customer with an additional level of comfort that the plant will perform as planned.

Step Four: Operational Support

Cogen has operated our own CHP plant since 2009. We understand how important the operators are to ensuring the plant delivers the financial savings and operational benefits it was designed to. Our operations team recommends we stay on after the plant commences commercial operations to ensure the Owners boiler operators become world class CHP plant operators.

This can be a few months of onsite support, or a few years, whatever makes the most sense for the Owner.The Cogen Operations Team will help assist the boiler plant operators with the following:

- Establish maintenance schedule

- Organize and manage work during plant shutdowns

- Manage Long Term Service Agreements with major equipment vendors

- Ensure daily checks are being done properly and logged accordingly

- Oversee plant troubleshooting efforts to minimize plant down time and maximize operator understanding of root causes and corrective actions

- Interface with the local utility as needed during power outages and or power quality issues

- Development of meaningful monthly reports with the appropriate plant performance metrics summarized.

- Whatever else ensures a smooth transition for the boiler plant staff

Our Portfolio

Explore successful projects implemented and currently supported by Cogen Power Technologies